Planning a new strategy? Want to improve customer satisfaction? Want to know why some of your projects are failing?

Process mapping is the first step to find out how and why to these questions above.

In this process mapping guide we will show you;

- What is a Process Map?

- Process Map Symbols

- Types of Process Maps

- How to Create a Process Map

- Process Mapping Best Practices

- Benefits of Process Mapping

- Process Map Templates

- Process Mapping Symbols (Continued)

What is a Process Map?

A process map visually shows the steps of a work activity and the people who are involved in carrying out each step. They are commonly used in process improvement initiatives, such as Lean Six Sigma or business process reengineering, to help organizations streamline their processes by identifying inefficiencies, bottlenecks, and areas for improvement.

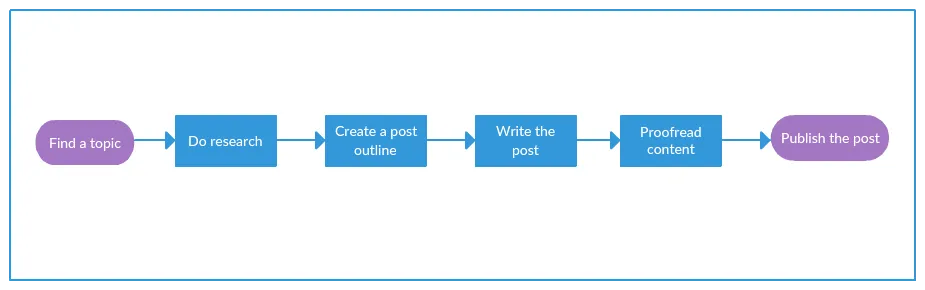

When mapping a process you simply draw a box for each step and connect them with arrows to show a flow. You can use an online tool to easily create a Process Map. A basic process map would look like this;

Process Map Symbols

Each step in a process is represented by a shape in a process map. These shapes are also called flowchart shapes.

There are nearly 30 standard shapes that you can use in process mapping. However, we think for most people, using a handful of the most common shapes will be easier to understand.

| Symbol | Name | Use |

|---|---|---|

|

Activity/Process | To represent a step/ activity of a process |

|

Decision | To represent a decision that has to be made |

|

Start/End | To represent the start and end of a process |

|

Arrow | To represent the connection between two steps and the direction of flow |

|

Document | To represent data or information that can be read by people |

The full set of process map/flowchart shapes are at the bottom of this guide.

How to Create a Process Map

Now that you know what process mapping symbols are and what types of process maps are out there, are you ready to create a process map? Here are the steps you need to follow,

Step 1: Identify the Process You Need to Map

Decide where you want to start. Is it with the process that is underperforming? Is it with the process that is important to your new strategy? Or is it with the process that directly makes an impact on customer satisfaction?

And then give it a name.

Step 2: Bring Together the Right Team

The input of everyone involved in the process is necessary to make sure that you cover every aspect of the process when mapping it. The right team should include those who do and manage the process and provides the input.

Step 3: Gather All the Necessary Information

- Where does the process begin and end?

- What are the steps in between these two points?

- What are the inputs and the outputs of the process?

- Who does what? When, where and how?

Step 4: Organize the Steps in a Sequential Order

Get your team to arrange each step in a sequential order from the beginning to the end.

Step 5: Draw the Baseline Process Map

Draw a process map that shows the map as it is currently. Keep in mind the process mapping best practices.

Step 5: Analyze the Map to Find Areas for Improvement

Identify inefficiencies and bottlenecks within the processes. What are the steps that should be eliminated? Where can you make improvements?

Step 6: Implement Improvements and Monitor Them

Implement the improvements on a smaller scale at first. If they work better, you can apply it on a larger scale. Monitor the new and improved process to see how it is functioning and whether it needs further optimization.

Process Map Templates

Following are a few process map templates you can edit online with the Creately editor.

Template 1

Click the template to edit it online

Template 2

Template 3

Want more free editable? process map templates

Types of Process Maps

Following is a list of different types of process maps along with a brief description and when you can use each. Choose the type of process map that is most suitable for your goal.

Basic Flowchart

A basic flowchart is a simple map visualizing the steps of a process including its inputs and outputs.

When to use:

- to plan new projects

- to model and document a process

- to solve problems

- to help teams communicate ideas better

- To analyze and manage workflows

How to draw:

Here’s the ultimate flowchart guide you need to learn how to draw them.

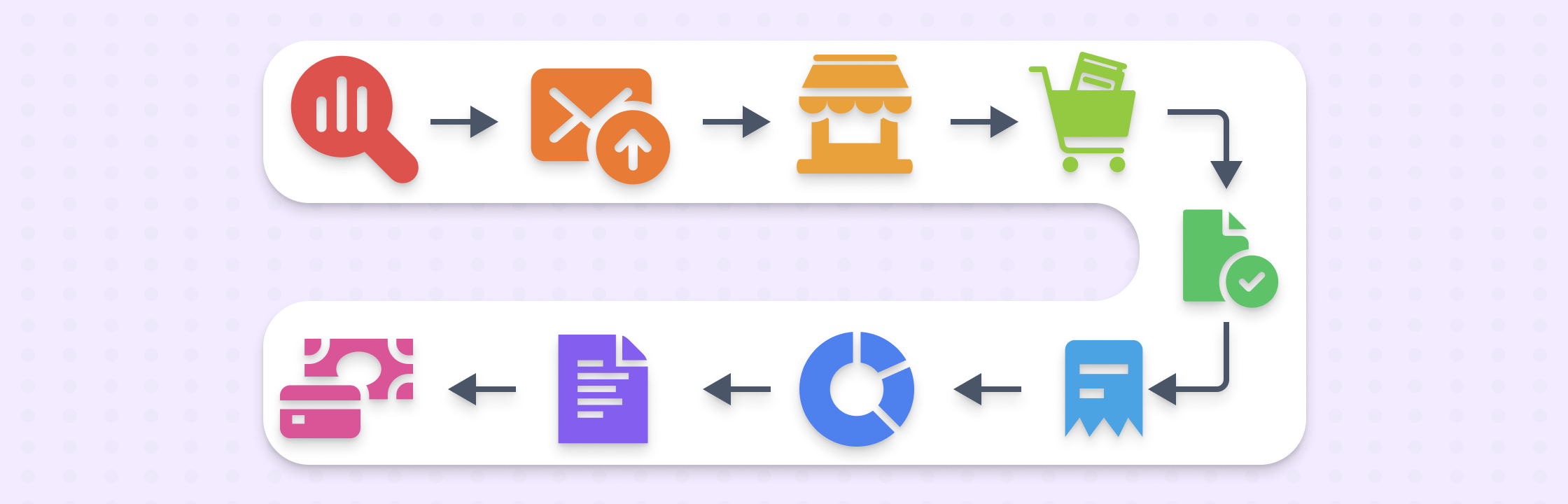

High-level Process Map

This is also known as a value chain map or a top-down map. It shows the core activities of a process. It doesn’t go into much detail about decision points, rework loop, roles involved etc.

When to use:

- to design and define business processes

- to identify the key steps and key details of a process

How to draw:

- list the most basic steps in the process (no more than 5-6 steps)

- organize them in order, horizontally

- list each sub-step (again, no more than 5-6 steps) under the main steps

Detailed Process Map

A flowchart that shows a drill-down version of a process. This means all the details of the sub-processes are contained in this type of map.

When to use:

- to give all details (inputs and outputs) related to a process step

- to document the decision points within a process

How to draw:

- define process boundaries

- what’s triggers the process? Use a SIPOC to identify process inputs

- identify what immediately happens after each input (repeatedly ask ‘what happens next?’ until you get to the output)

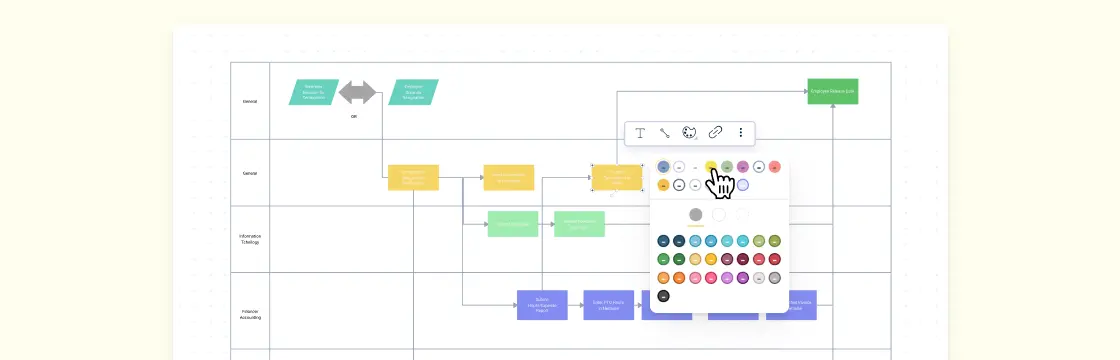

Cross-Functional Flowchart

A flowchart that shows the relationships between process steps and the functional units (teams/ departments) responsible for them with swimlanes. It’s also known as a deployment flowchart.

When to use:

- to identify the key roles responsible for the process and how they relate to each other

- to highlight how a process flows across company boundaries

- to identify potential process failure, redundancies, delays, rework, excessive inspection etc.

How to draw:

- Gather a competent and relevant cross-functional team

- Identify stakeholders

- list the process stakeholders (based on how close they are to the process customer) starting with the process customer

- add swim lanes to separate the columns between each stakeholder

- add steps performed by each stakeholder in their respective swim lane

- connect the steps with arrows to indicate the flow

SIPOC

SIPOC shows the key elements of a process such as Suppliers, Inputs, Process, Outputs, and Customers.

When to use:

- to identify the key elements of a process before doing a detailed map

- to define the scope of complex processes

- can be used in the Measure phase of the DMAIC methodology

How to draw:

- Draw a table of 5 columns for Suppliers, Inputs, Process, Outputs, and Customers

- Start with mapping the process in 5-6 high-level steps

- Identify the outputs

- Identify the customers

- Identify the inputs of the process

- Identify the suppliers of each of the inputs

- Verify the SIPOC diagram with project head and other stakeholders

Value Stream Map

Value stream maps visualize the flow of material and information that is needed to bring your product to the customer.

When to use:

- to record measurements of the inputs and outputs of process steps

- to identify waste within and between processes

- to document, analyze and improve the flow of information and material

- to gain insight into decision-making and process flow

- to identify where to focus future projects or subprojects

How to draw:

Here’s a comprehensive value stream mapping guide to master how to draw them. Note that Value stream maps have a different set of shapes, but the principles of process mapping remain the same.

Process Mapping Best Practices

- Before identifying the process steps, start with identifying the start and end points of the process. This helps with setting limits

- Make your process maps as easy and simple as possible to read and understand by anyone in your company

- Keep only the necessary details on your map. Not less or more than needed to identify areas for improvements

- Make sure you use the correct process map symbols when drawing to avoid confusion

- Include all the key stakeholders when mapping the process to avoid missing out on important information or steps

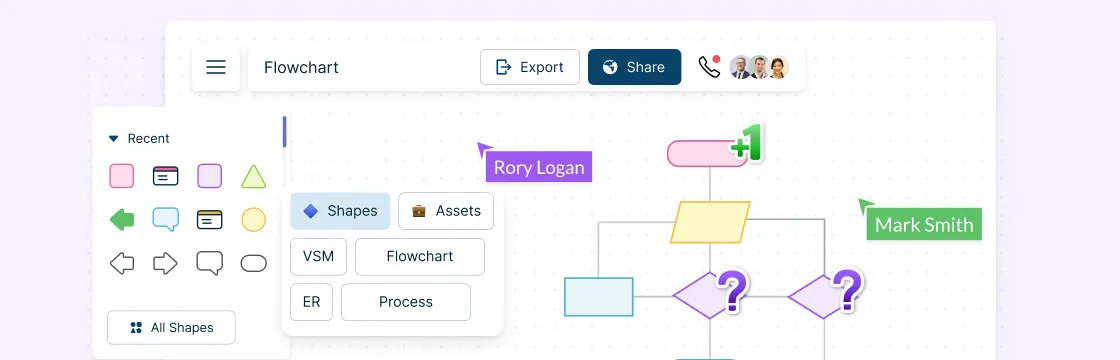

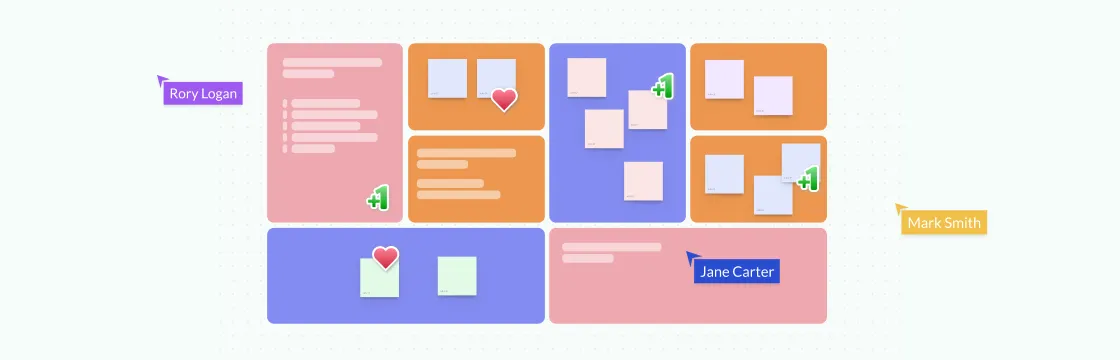

- Use a business process mapping software that allows you to quickly draw as well as collaborate with your team in real-time for efficiency

More process mapping best practices.?

Benefits of Process mapping

As you are already reading about process mapping, we’d guess you know at least a few benefits of doing it. However read this section carefully as it will help you convince others!

- Makes understanding and communicating the process much easier among teams, stakeholders or customers

- Serves as a useful tool for scenario testing and what-if assessments

- Can be used as a marketing tool to prove to your investors or industrial customers that your business processes are reliable

- Is a requirement of many types of standards and certification like ISO 9000

- Makes process documentation more reader-friendly

- Spread awareness of the roles and responsibilities of those who are involved

- Helps identify flaws in the process and where improvements should be made

- Aids teams brainstorm ideas for improvement or new changes that will help tackle challenges like retaining employees, declining revenue etc.

- Helps reduce costs associated with development of products and services

- Improve team performance and employee satisfaction

- Can be used as a learning material to train new employees

- Helps measure the efficiency of work processes

Process Mapping Symbols (Continued)

In addition to the basic symbols we discussed earlier, process mapping makes use of the following symbols as well.

Process/ Operations Symbols

| Symbol | Name | Use |

|---|---|---|

|

Predefined Process / Subroutine | To represent a process that is already pre-defined |

|

Alternate Process | To represent a process step that is an alternative to the normal process step |

|

Delay | To represent a delay or a pause before the process flow continues |

|

Manual Loop | To represent automated steps that need to be stopped manually |

|

Preparation | To represent something that needs to be modified or adjusted in the process before continuing |

Branching and Control of Flow Symbols

| Symbol | Name | Use |

|---|---|---|

|

On-Page Connector | To represent an inspection point in the process flow |

|

Of-Page Connector | To represent cross-references and links to the process from another process on another page |

|

Merge | To represent a step that will merge several steps into one |

|

Extract | To represent a process that is divided into parallel paths |

|

Or | To represent the ‘or’ logic |

|

And | To represent the ‘and’ logic |

Input and Output Symbols

| Symbol | Name | Use |

|---|---|---|

|

Data | To represent inputs to and outputs from the process |

|

Multiple Document | To represent multiple documents |

|

Display | To represent data that is displayed to be read on a screen or display |

|

Manual Input | To represent process steps that will be manually performed by a person |

File and Information Storage Symbols

| Symbol | Name | Use |

|---|---|---|

|

Stored Data | To represent stored data |

|

Database | To represent a database |

|

Direct Access Storage | To represent a hard drive |

|

Internal Storage | To represent an internal storage device |

Data Processing Symbols

| Symbol | Name | Use |

|---|---|---|

|

Collate | To represent a step in which data is organized in a standard way |

|

Sort | To represent the sorting of items in a particular order |

What Are Your Thoughts on the Process Mapping Guide?

Process maps are not only a vital part of process documentation but are also a popular business process improvement methodology.

Follow the guide to create efficient business process maps and share with us any concern you may have, even if it is another process mapping technique that you personally use.

In our next guide, we’ll be discussing diagrams that can be used to make HR management more efficient.

FAQ about Procee Mapping Guide

Choosing the right process mapping diagram template depends on the specific needs and requirements of the project or process being mapped. Here are some factors to consider when choosing the right process mapping diagram:

Purpose of the Map: Consider the purpose of the map, whether it is to understand a process, identify bottlenecks, or improve the process. Different types of process mapping diagrams are suitable for different purposes. You can find different types of process mapping diagram in Creately.

Level of Detail: Determine the level of detail required for the map. Some diagrams, such as flowcharts or swimlane diagrams, provide a high-level overview of the process, while others, such as value stream maps or process flow diagrams, offer a more detailed view of the process.

Complexity of the Process: Consider the complexity of the process being mapped. Some diagrams, such as flowcharts, are suitable for simple processes, while others, such as value stream maps or process flow diagrams, are better for more complex processes.

Audience: Consider the audience who will be using the process map. Some diagrams, such as flowcharts, are easier to understand for non-technical audiences, while others, such as BPMN diagrams, are more suitable for technical audiences.

Available Tools: Select a tool that helps simplify the process of drawing a process map. Creately is one of the most used process mapping tools and it offers easy-to-use drag and drop tools, formatting options, premade templates and powerful collaboration capabilities to create suitable process mapping diagrams effortlessly.

-

Not defining the scope: One of the most common mistakes is not defining the scope of the process being mapped. Failing to define the boundaries of the process can lead to confusion and inaccurate mapping.

-

Including too much detail: Another mistake is including too much detail in the process map, making it difficult to read and understand. It’s important to keep the map concise and focused on the key steps and decision points in the process.

-

Lack of consistency: Inconsistent symbols and formatting in the process map can cause confusion and make it harder to understand. It’s important to establish a consistent approach to formatting and symbols, and ensure that they are followed consistently throughout the map.

-

Ignoring input from stakeholders: Failing to involve key stakeholders in the process mapping exercise can lead to a lack of buy-in and inaccuracies in the map. It’s important to involve stakeholders in the process and gather their input and feedback to ensure that the map accurately reflects the process.

-

Using incorrect symbols or terminology: Using the wrong symbols or terminology can lead to confusion and inaccuracies in the process map. It’s important to use commonly accepted symbols and terminology to ensure that the map is clear and accurate.