Capacity planning is the process of determining the resources you need to meet the current and future demands of your business. It helps you optimize your performance, reduce costs, and avoid downtime.

But how do you plan your capacity effectively? What strategies and steps should you follow? And what are the benefits and challenges of capacity planning? In this blog post, we will answer these questions and more.

- What is Capacity Planning?

- Capacity Planning Strategies

- Steps in the Capacity Planning Process

- Benefits of Capacity Planning

- Capacity Planning Best Practices

- Challenges in Capacity Planning and How to Overcome Them

- Conclusion

- FAQs About Capacity Planning

What is Capacity Planning?

Capacity planning is the process of estimating the amount of resources (such as staff, equipment, space, etc.) that you need to deliver your products or services at the desired quality and quantity levels.

Capacity planning helps you answer questions like:

- How much demand do I expect in the future?

- How much capacity do I have right now?

- How much capacity do I need to meet the expected demand?

- How can I balance the supply and demand of my resources?

Capacity planning is essential for any business that wants to grow, improve efficiency, and satisfy customers. It helps you avoid running overcapacity or under capacity, which can lead to wasted resources, lost revenue, poor quality, or unhappy customers.

Capacity Planning Strategies

There are different strategies that you can use to plan your capacity, depending on your business goals, industry, and market conditions. Some of the common strategies are:

Lead Strategy

This strategy involves increasing your capacity ahead of the expected demand. This way, you can take advantage of new opportunities, gain a competitive edge, and avoid losing customers due to insufficient capacity. However, this strategy also involves higher costs and risks of overestimating the demand.

Lag Strategy

This strategy involves increasing your capacity after the demand has increased. This way, you can reduce your costs and risks of overinvesting in capacity. However, this strategy also involves lower customer satisfaction and market share, as you may not be able to meet the demand in time.

Match Strategy

This strategy involves increasing your capacity in small increments as the demand increases. This way, you can balance your costs and risks with your customer satisfaction and market share. However, this strategy also involves higher complexity and uncertainty, as you need to constantly monitor and adjust your capacity.

Steps in the Capacity Planning Process

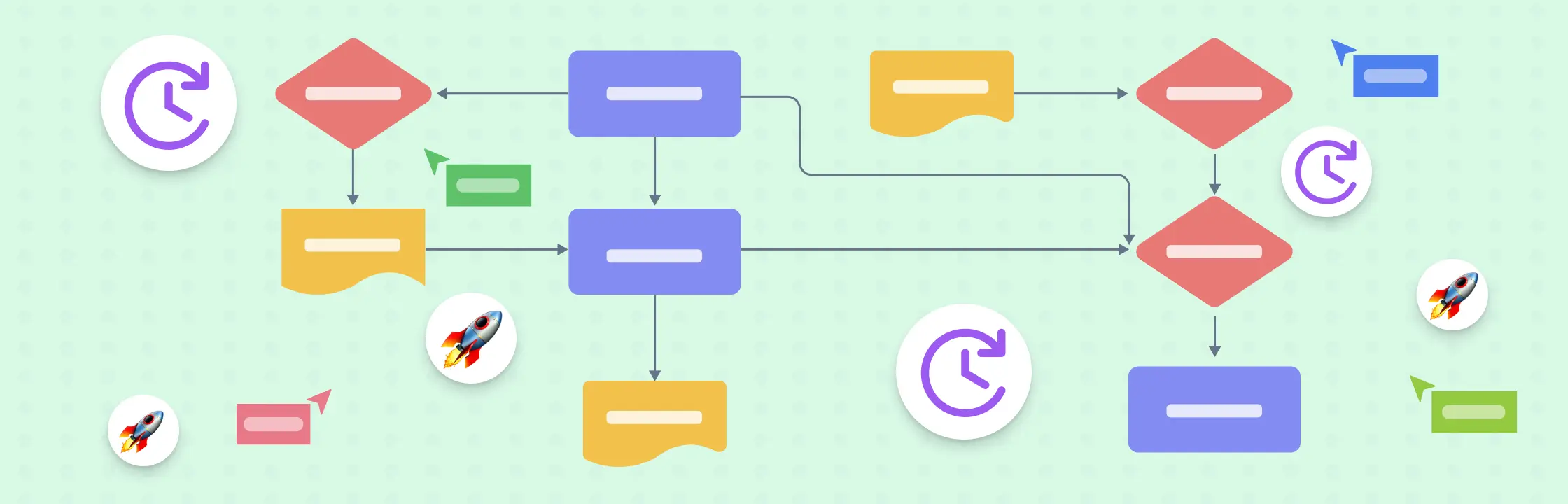

The capacity planning process can vary depending on your business type, size, and needs. However, a general framework that you can follow consists of these steps:

1. Analyze Your Current Capacity

The first step is to measure and evaluate your current capacity levels. You need to identify available resources, resources currently in use, and how efficiently you are using them. You can use metrics such as utilization rate, throughput rate, cycle time, etc. to assess your current capacity.

2. Forecast Your Future Demand

The next step is to estimate your future demand for your products or services. You need to consider factors such as historical trends, market conditions, customer preferences, seasonal variations, etc. to project your future demand. You can use methods such as trend analysis, regression analysis, scenario analysis, etc. to forecast your future demand.

3. Determine Your Optimal Capacity Level

The third step is to calculate the optimal amount of resources that you need to meet your future demand. You need to consider factors such as quality standards, service levels, customer expectations, etc. to determine your optimal capacity level. You can use methods such as break-even analysis, cost-benefit analysis, simulation modeling, etc. to determine your optimal capacity level.

4. Identify the Gap Between Your Current and Optimal Capacity Levels

The fourth step is to compare your current and optimal capacity levels and identify the gap between them. You need to determine whether you have excess or insufficient capacity and by how much.

5. Develop and Implement a Capacity Plan

The final step is to develop and implement a plan to close the gap between your current and optimal capacity levels. You need to decide which strategy (lead, lag, or match) suits your business goals and budget best. You also need to choose which methods (such as hiring or firing staff, buying or leasing equipment, expanding or reducing space, etc.) you will use to increase or decrease your capacity.

Benefits of Capacity Planning

Capacity planning can bring many benefits to your business, such as:

Improved performance: Capacity planning helps improve your productivity, efficiency, quality, and profitability by ensuring that you have enough resources to meet the demand at the right time and place.

Reduced costs: Reduce your operational costs by avoiding overcapacity or under capacity situations that can lead to wasted resources or lost revenue.

Enhanced customer satisfaction: Enhance customer satisfaction by delivering your products or services at the desired quality and quantity levels without delays or shortages.

Increased flexibility: Increase your flexibility by allowing you to adapt quickly and easily to changing market conditions and customer needs.

Capacity Planning Best Practices

To plan your capacity effectively, you should follow some best practices, such as:

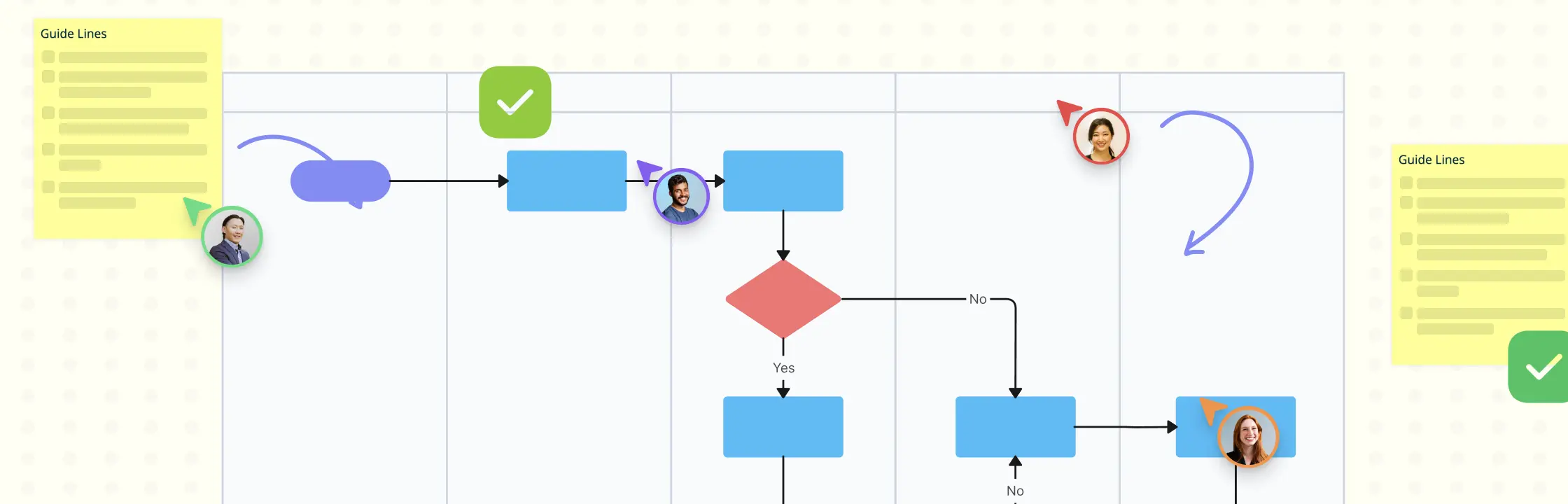

Involve all stakeholders: Capacity planning is a cross-functional process that requires the input and collaboration of all stakeholders, such as managers, employees, customers, suppliers, etc. You should involve them in the capacity planning process and communicate your goals, expectations, and results clearly and regularly.

Use reliable data: It is based on data and analysis. You should use reliable and accurate data sources and methods to measure your current capacity, forecast your future demand, and determine your optimal capacity level. You should also update your data and analysis periodically to reflect the latest changes and trends.

Consider multiple scenarios: Capacity planning is subject to uncertainty and variability. You should consider multiple scenarios and contingencies when planning your capacity and prepare for different outcomes and risks. You should also review and revise your capacity plan as needed to cope with unexpected events or opportunities.

Balance short-term and long-term goals: Maintain a balance between short-term and long-term goals. You should align your capacity plan with your strategic vision and objectives, but also consider your operational constraints and realities. You should also balance your costs and benefits, risks and rewards, and supply and demand.

Challenges in Capacity Planning and How to Overcome Them

Capacity planning is not without challenges. Some of the common challenges that you may face are:

Demand uncertainty: Demand is often unpredictable and volatile. You may face fluctuations in demand due to factors such as customer behavior, market conditions, competitor actions, etc. To overcome this challenge, you should use multiple sources and methods to forecast your demand, monitor your demand patterns regularly, and adjust your capacity accordingly.

Resource constraints: Resources are often limited and scarce. You may face constraints in resources such as staff, equipment, space, etc. due to factors such as availability, cost, quality, etc. To overcome this challenge, you should optimize your resource utilization, prioritize your resource allocation, and explore alternative or complementary resources.

Technology changes: Technology is constantly evolving and improving. You may face changes in technology that can affect your capacity levels or requirements. For example, new technology can increase your capacity or reduce your demand. To overcome this challenge, you should keep up with the latest technology trends, evaluate the impact of technology changes on your capacity, and adopt or adapt to new technology as appropriate.

Conclusion

Capacity planning is a vital process for any business that wants to grow, improve efficiency, and satisfy customers. It involves estimating the resources you need to meet the current and future demands of your business.

To plan your capacity effectively, you should follow a general framework that consists of these steps:

- Analyze your current capacity

- Forecast your future demand

- Determine your optimal capacity level

- Identify the gap between your current and optimal capacity levels

- Develop and implement a capacity plan

You should also follow some best practices such as involving all stakeholders, using reliable data, considering multiple scenarios, and balancing short-term and long-term goals.

By planning your capacity well, you can enjoy many benefits such as improved performance, reduced costs, enhanced customer satisfaction, and increased flexibility.

However, you should also be aware of some challenges such as demand uncertainty, resource constraints, and technology changes. You should overcome these challenges by using multiple sources and methods to forecast your demand, optimizing your resource utilization, prioritizing your resource allocation, exploring alternative or complementary resources, keeping up with the latest technology trends, evaluating the impact of technology changes on your capacity, and adopting or adapting to new technology as appropriate.

We hope you enjoyed this blog post on how to plan your capacity like a pro. If you have any questions or feedback, please leave them in the comments section below.